Eyes you can trust.

Performance you can measure.

A 3D AI-based platform designed for precision, scalability and speed capable to do SPI and AOI.

Across every SMT and THT production phase, Delvitech offers a cutting-edge platform capable of AOI and SPI that combines AI-native intelligence with world-class hardware engineering. The result? Faster, more stable processes, drastically reduced false calls, minimal material waste with consequent lower CO₂ emissions, improving your production quality and sustainability.

One platform.

Total control for all assembled PCB Inspection Stages.

Adaptable across production phases, from solder paste to Automated Optical Inspection, Delvitech empowers engineers with a single, smart inspection program flexible, consistent, and ready for every production phase.

What powers

your performance.

NEITH Software

Web-based AI-powered platform that boosts production output, prevents defects, and increases the first-pass yield.

Training Manager

On-machine training that learns without forgetting, continuously improving without halting production.

Self-programming

Coming soon: reduce setup time with automatic component recognition, package matching, and parameters optimization.

See how it

all connects.

scroll horizontally

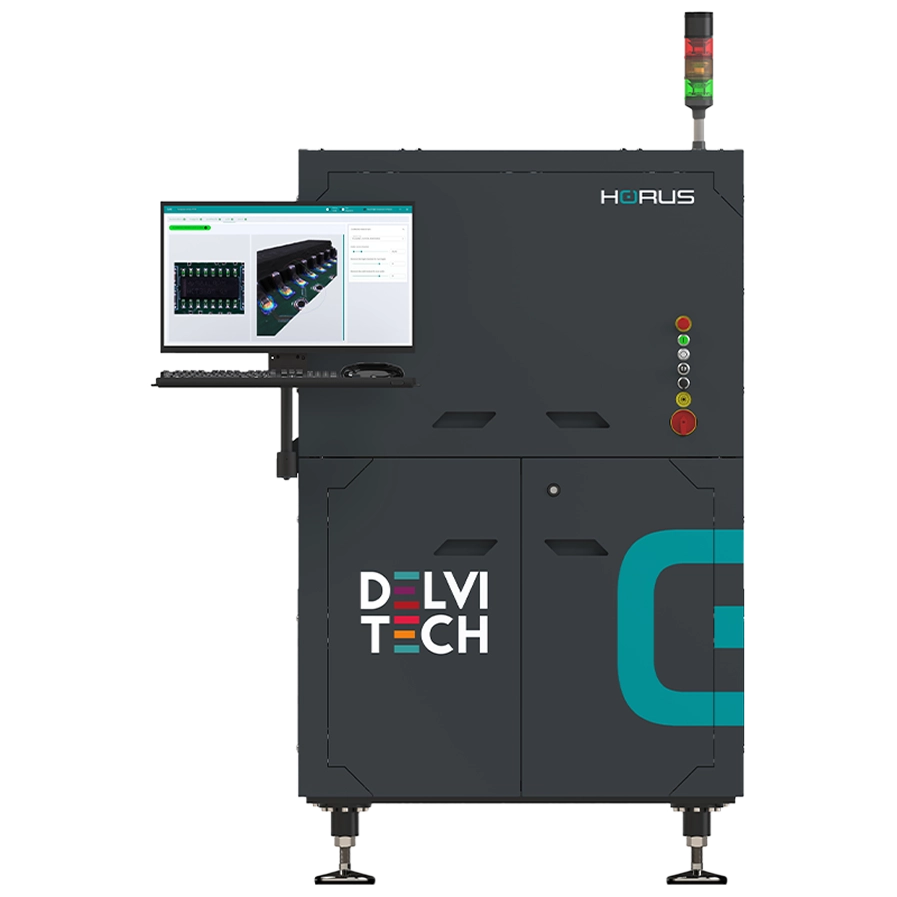

Horus

3D AOI + SPI for PCB Inspection

Driven by AI. Guided by vision.

Horus is the first AI-native platform designed to perform both AOI and SPI for SMT productions, with true 3D precision. It inspects faster, sees deeper, and continuously adapt, reducing false positives by a factor of ten and enabling tailored inspections with minimal manual input.

Patented optical heads + AI brain

Delvitech’s patented optical heads gather ultra-precise 3D data and high-resolution images. Powered by proprietary neural networks and patented optical heads, the system adapts to any surface, height, or material, delivering clear results across a wide spectrum of components, from reflective metals to shadowed zones, tall connectors, and fine-pitch elements. And it keeps learning, cycle after cycle.

A scalable, upgradable platform

XP for speed, HD for detail. ITU for both sides, DUO for both lanes.

For high-throughput environments, the XP element enables fast-paced inspection at 0.7 sec/FoV. The HD element delivers ultra-high-resolution imaging, ideal for microelectronics and detailed assemblies. DUO introduces a dual-lane conveyor to optimize board handling and increase line efficiency, while the ITU element supports double-sided inspection by rotating PCBs along the X axis. With Horus, your AOI system scales to match your evolving workflow.

Instant Insight, Zero Bottlenecks

40 Gbit in 1 second. Thinks faster than you blink.

Horus processes over 40 gigabytes of inspection data in 1’’. From component location and polarity to pin contours and solder joint analysis, every detail is captured with exceptional clarity. Integrated OCR and full 360° inspection ensure compliance with IPC standards, while true 3D optical technology, linear motor-driven heads, and lightning-fast board handling push performance beyond the limits of traditional systems.

Ready for Any Board

Up to 60 mm. Clearance for every project.

With generous top and bottom clearance and support for boards up to 560 × 550 mm, Horus handles even the most complex assemblies, offering unmatched flexibility for any production line.

Aton

The 3D AOI solution for all types of boards

An outstanding hardware.

Aton is a cutting-edge full 3D inspection solution powered by Artificial Intelligence, designed to redefine the standards of Automated Optical Inspection (AOI) systems. Tailored for post-reflow and post-wave inspection, Aton excels in handling even the most complex PCBA, with heavy, large, or high-profile components.

Z-Axis movement

Engineered for height variation.

Thanks to its adaptive Z-axis movement and advanced optical head, Aton is ideal for special applications where components of varying heights must be inspected. The system offers dynamic focus adjustment across an 80 mm range, enabling precise analysis of boards with components reaching up to 140 mm in height.

Clearance for every project

Bottom clearance up to 140mm.Aton is built to handle even the tallest components, with top clearance up to 120 mm, bottom clearance up to 140 mm and boards up to 10 kg. Whether you’re inspecting tall connectors, reflective materials, or irregular geometries, Aton gives you the space – and the precision – to do it right.

Real 3D acquisition

Optical head technology.

The patented Delvitech optical head with 6 cameras is a powerful technology that acquires precise 3D data with crystal clear images for a wide range of packages and components. From tall connectors with reflective metallic surfaces to fine pitch components, Aton provides a reliable and consistent performance to cover all scenarios in SMT and THT.

Roberto Gatti

Chairman

CEO Delvitech Group.

Gabriele Besacchi

Board member

Managing Director and Private Investments Specialist Alvarium.

Investment Managers.

Jürgen Schmidhuber

Board member

Director, Al Initiative, KAUST.

Scientific Director Swiss Al Lab IDSIA.

Paolo Orsatti

Board member

Managing Partner TiVentures and CREADD.

Jan Baggerman

Board member

Entrepreneur.

Delvitech Worldwide

-

Switzerland

Delvitech SA

-

India

DelvitechAI Vision Systems India Pvt. Ltd.

-

United States

Delvitech Inc

-

Germany

Delvitech GmbH

Get In Touch